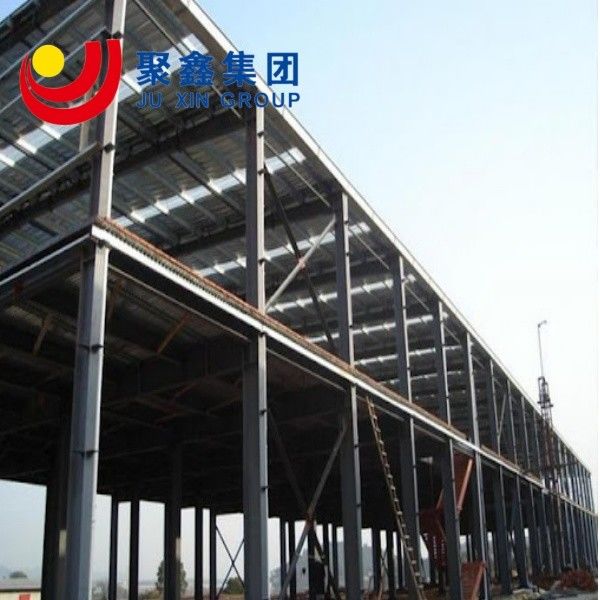

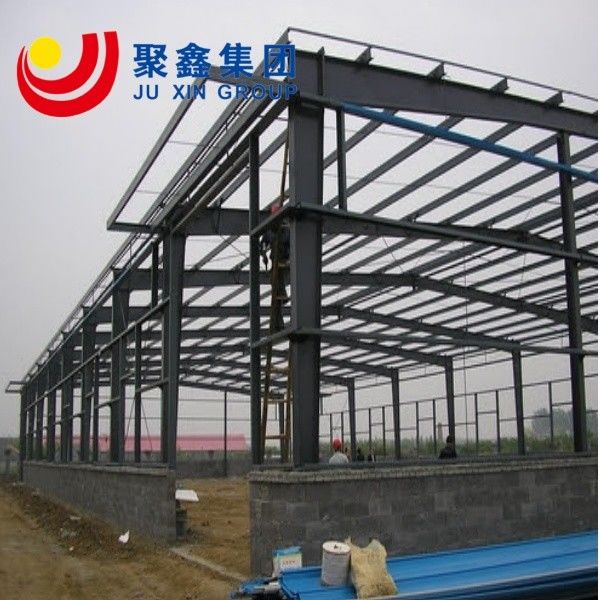

Steel structure frame buildings, particularly warehouses, have become a popular choice in the construction industry due to their numerous advantages. Here’s a detailed look at what steel structure frame buildings entail, specifically focusing on warehouses:

1. Design and Engineering

- Customizable Layouts: Steel warehouses can be designed to meet specific requirements, offering flexibility in layout, height, and span.

- Advanced Software: Utilization of CAD (Computer-Aided Design) and BIM (Building Information Modeling) software for precise planning and design.

2. Materials

- High-Strength Steel: The primary material used for the frame, offering durability and strength while being lightweight.

- Galvanized Coating: Steel components are often coated with zinc to protect against corrosion, enhancing longevity.

3. Construction Process

- Factory Fabrication: Components are prefabricated in a controlled environment, ensuring quality and minimizing waste.

- On-Site Assembly: Quick assembly through bolted connections, reducing on-site construction time.

4. Cost-Effectiveness

- Lower Initial Costs: Prefabrication and efficient use of materials lead to lower upfront costs compared to traditional construction methods.

- Reduced Maintenance: Steel structures require less maintenance, leading to lower long-term expenses.

5. Durability and Safety

- Weather-Resistance: Steel frames are resistant to wind, fire, and pests, providing a safer and more resilient building.

- Seismic Resistance: Engineered to withstand earthquakes, making them suitable for areas prone to seismic activity.

6. Flexibility and Scalability

- Easy Expansion: Steel warehouses can be easily expanded by adding new bays or sections, accommodating growth.

- Modular Design: Allows for customization and adaptation to changing needs without major reconstruction.

7. Energy Efficiency

- Insulated Panels: Walls and roofs can be fitted with insulated panels to reduce heating and cooling costs.

- Green Building Practices: Steel is recyclable, and modern warehouses can incorporate energy-saving technologies.

8. Speed of Construction

- Rapid Deployment: Prefabricated components enable quick assembly, minimizing downtime and speeding up the operational phase.

9. Aesthetics and Functionality

- Custom Exteriors: Can be finished with various cladding options to suit aesthetic preferences or branding needs.

- Optimized Layouts: Design can be optimized for efficient material handling and workflow, enhancing productivity.

10. Regulatory Compliance

- Building Codes: Steel warehouses are designed to comply with local building codes and regulations, ensuring safety and adherence to standards.

11. Disaster Recovery

- Quick Reconstruction: In case of damage, steel structures can be quickly repaired or reconstructed using standardized components.

12. Economic Impact

- Job Creation: Construction and maintenance of steel warehouses can support local employment in both skilled and unskilled roles.

In summary, steel structure frame buildings, especially warehouses, offer a combination of cost-effectiveness, durability, and flexibility. They are designed to withstand harsh conditions, can be customized to meet specific needs, and can be rapidly deployed, making them a preferred choice for industrial and commercial applications.

Product Parametes

|

Steel structure building

|

|

1. Primary Framing

|

Painted or hot-galvanized H column and beam

|

|

2. Secondary Framing

|

Galvanized Z and C sections purlin

|

|

3. Roof and Wall panels

|

Steel sheet and insulated sandwich panels (EPS, fiberglass wool and PU)

|

|

4. Steel Decking Floor

|

Galvanized steel decking board

|

|

5.Structural subsystem

|

Canopies, fascias, partitions, etc.

|

|

6.Mezzanines, Platforms

|

Painted or galvanized H beam

|

|

7.Other Building Accessories

|

Sliding doors, roll up doors, aluminium windows, louvers, etc.

|

|

Drawings & Quotation:

|

|

(1) Customized design is welcomed.

|

|

(2) In order to provise an accurate quotation and drawings, please let us know the length, width, eave height and local weather.

We will quote for you promptly.

|

Company Profile

Shandong Juxin Steel Structure Co., Ltd. is specialized in building steel structure design, manufacturing, installation, maintenance as one of the professional enterprises. Integrated design, manufacturing, installation in one, with H-shaped steel; C, Z steel; Bolt ball joint grid; Color light roof panel, wall panel; office integrated activity room and other production lines, has its own professional design office, professional processing equipment, professional testing equipment, professional quality inspection personnel, professional manufacturing base, professional production and technical personnel, professional installation team and perfect operation, after-sales service team.

Product Description

Our advantage

Certifications

Customer Case

We will consider the standards and specifications of each region. Therefore, by choosing us, you will obtain steel structure products that fully comply with the legislative requirements of your country/region. At the same time, we have many experiences in industrial buildings, public buildings, bridge buildings, marine engineering, livestock building, high-rise buildings, aerospace, military construction, and other fields.

We will carefully study your specific needs and specifically design and manufacture load-bearing structures suitable for your project.

FAQ

Q1: How long does it take to get my building?

A: Lead time is vary, but typically 2 weeks of drawings and 6-8 weeks for delivery(depending on complexity)

Q2: What are the benefits of steel construction?

A: 1-Durable and with long lifespan.

2-Short construction period than concrete and wooden building.

3-Low cost and reusable.

4-High strength and light weight, has good seismic performance.

5-Widely used for multi-purpose buildings.

Q3: Why choose JU XIN?

A: At JU XIN, the customer is the first priority. We don't pull any gimmicks. We are veteran owned and operated business, unmatched in customer service. We have more than 20 years of metal building experience. We are also very reputable manufacture and can answer your questions regarding any tape of construction project.We care about your needs and value your business.

Q4: How can l get the quotation of the project?

A: lf you have the drawing, we can offer you our quotation accordingly. lf youhave no design, our engineer will design for you to confirm. And then offer you a quotation.

Q5: Do you offer designing service for us?

A: Yes, we can provide full solution drawings as your requirements. By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (X steel) and etc. We can design complex industrial building like office building,

supermarket, auto dealer shop, shipping mall, hotel etc.

Q6: Do you provide samples?

A: Yes, we could offer the sample for free but do not pay for the cost of transportation.

Q7: What is your terms of payment ?

A: L/C, T/T, and Western Union.

Q8: How about your quality control?

A: We have our own professional quality control team with rich experience and advanced inspection equipment. Also we are willing to accept any other the third inspection part to control.

Q9: Can you provide the installation help?

A: We will provide detailed instruction photos and videos to you. If it is necessary,we will send professional engineers to do the construction guidance, and some skilled workers to help for installation. However, the visa fee, air tickets,accommodation, wages will be provided by buyers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!